The requirements and landscape for track maintenance, rehabilitation, and track laying have changed significantly over the last decade. Sustainability aspects and changes to economic conditions for operating companies require a comprehensive assessment of the cost-benefit ratio for new investments.

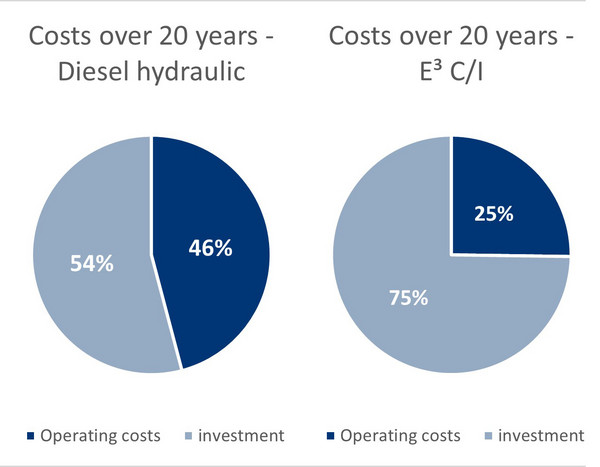

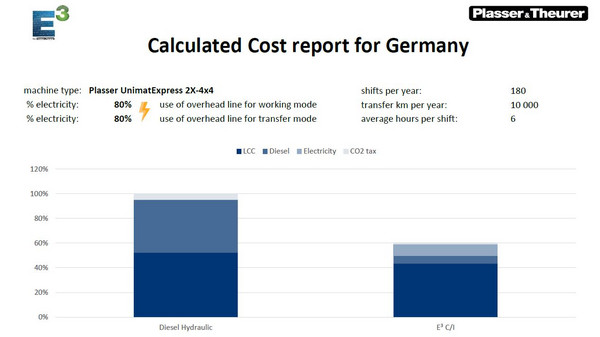

A total cost of ownership (TCO) calculation provides a holistic perspective on costs for sound investment decisions. This method of analysis provides clear comparability of established and alternative drive forms. Its aim: cost-effective, sustainable, and ergonomic solutions for the railway of the future.

Developments over the past ten years have paved the way towards a sustainable mechanized maintenance train with the hybrid E³ drive system. The increasing demand for track maintenance machines with alternative drive systems is leading to current offerings which, in addition to their ecological advantages, must prove themselves in terms of economic efficiency.