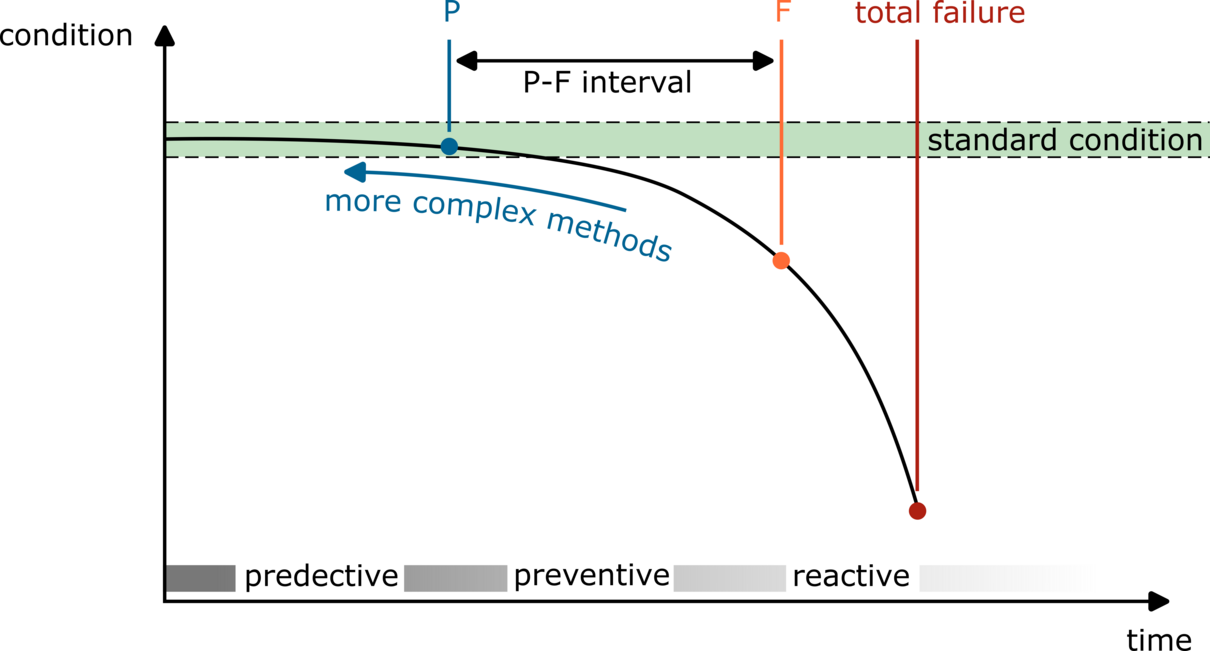

The aim of predictive maintenance strategies is to estimate the optimum time for maintenance measures. With special machine construction, characterized by small production quantities, conventional statistical or AI-supported data analyses quickly reach their limits. What is needed is a concept that derives specific recommendations for action from the wealth of machine data.

Modern track maintenance machines are equipped with an extensive array of sensors. These sensors provide plenty of data that can be used for efficient machine maintenance. Plasser Datamatic stores data via a module integrated into the machine control system and makes it available to the machine operating company for further analyses. The difficulty lies in drawing the right conclusions from this flood of data. In the case of mass-produced products and uniform processes, statistical parameters are often used to determine suitable indicators and make predictions. However, these methods are often unsuitable for track maintenance machines due to a lack of valid statistical reference values. It is therefore crucial to incorporate the expertise and experience of domain experts. Complex problems can be tackled systematically with a holistic approach that takes into account the physical relationships and specificities of machine operation. In order to generate real added value from the data, a three-stage approach is followed: Detect – Diagnose – Predict.

Detect – Where do you need to look?

Just as pain signals in the body indicate problems, anomalies in the machine data show which assemblies or components require action. But how do you find the needle in the data haystack?

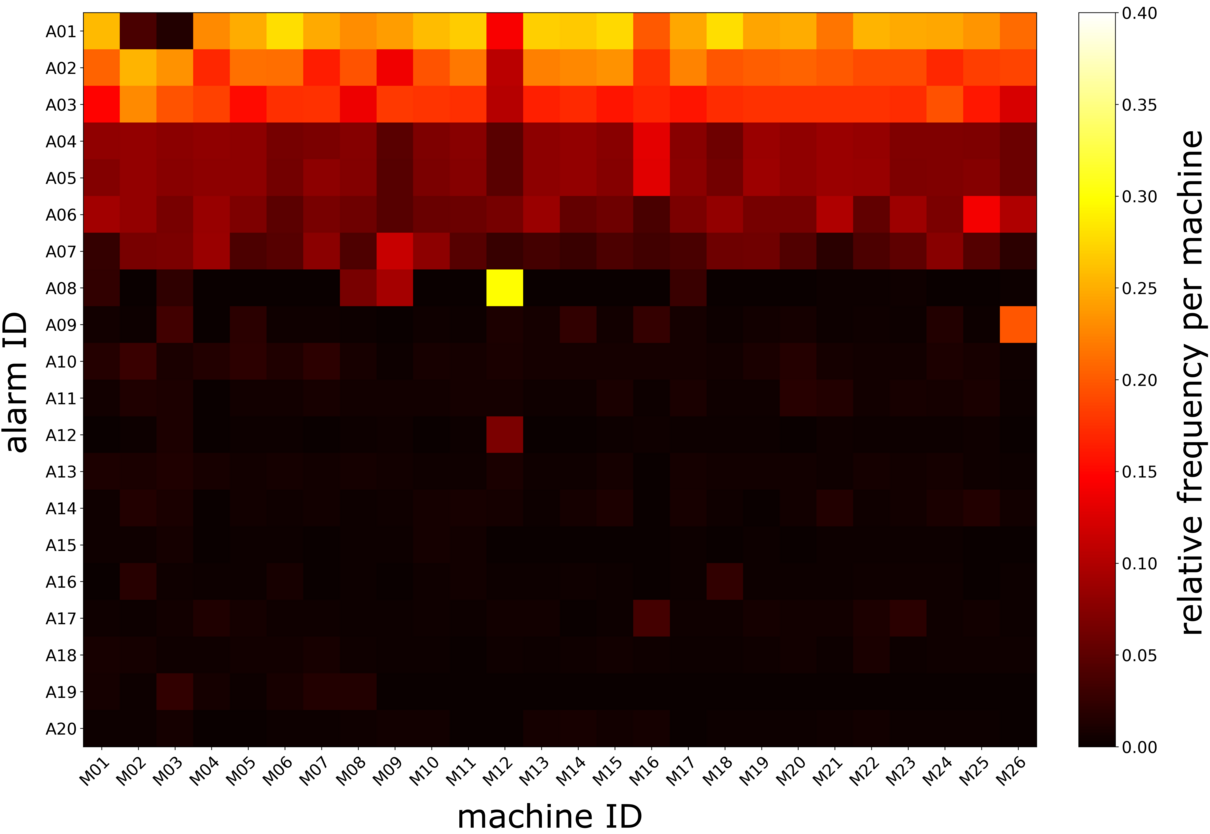

One possibility is automated monitoring of important parameters whose limits have been defined. If they are exceeded, an alarm is triggered. Additionally, it is possible to recognize atypical behaviour patterns in a fleet of identical machines (Fig. 2).

However, alarm messages or anomalies in the machine data are not enough. For example, a relevant change in the coolant temperature of an engine may indicate a problem in the cooling system or a faulty sensor. Again, it is important to incorporate expert knowledge.

Diagnose – How do you analyse data to identify a problem?

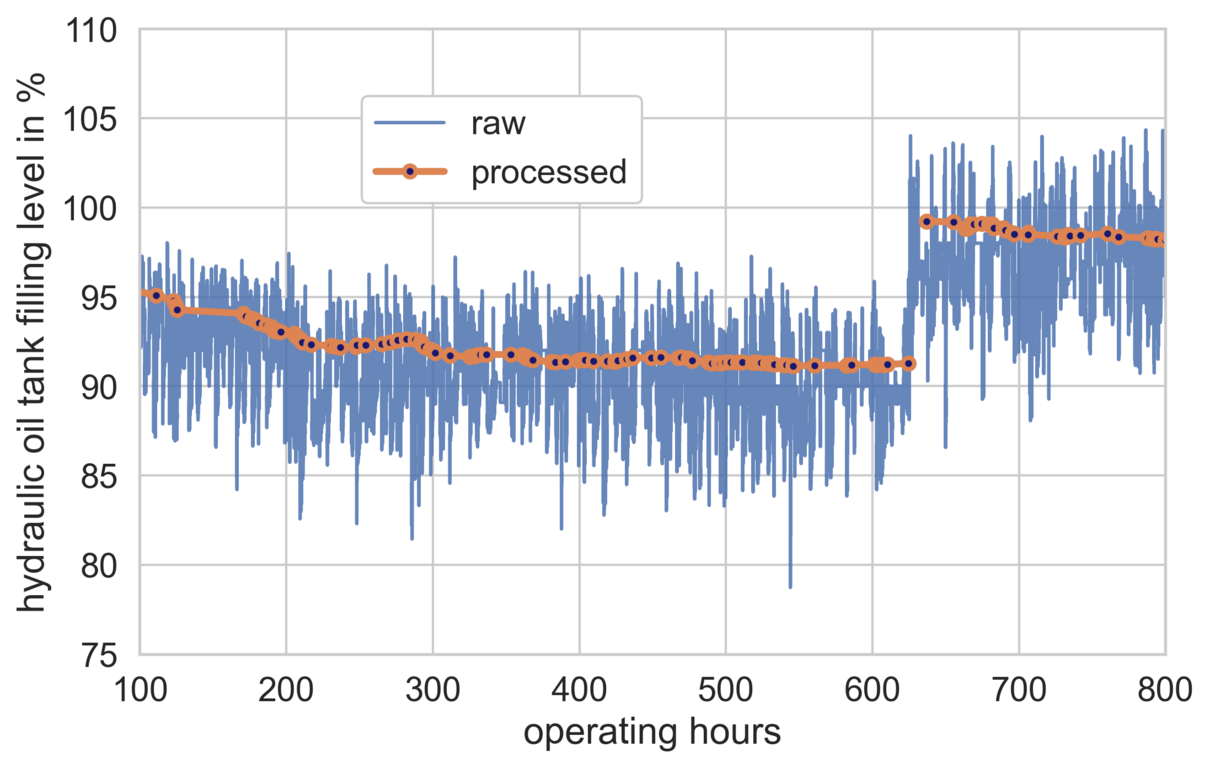

A diagnosis involves determining the cause, severity, and potential effects of a problem. However, it is often not obvious that there is a problem. Raw data often requires pre-processing in order to enable meaningful analyses.

Here’s a simple example: leaks in the hydraulic system can be recognized in the filling level of the oil tank. Early detection of major leaks allows proactive action and avoids costly system failures. However, the filling level signal varies greatly depending on the operating status. It is difficult to determine an average leakage rate from this. It is therefore crucial to use only selected data points and to consider them temperature-corrected and smoothed (Fig. 3).

Such analyses require a good knowledge of the system. This becomes even clearer with more complex tasks such as vibration analyses. The correct interpretation of machine data is essential for a meaningful diagnosis and forms the basis for predictive maintenance.

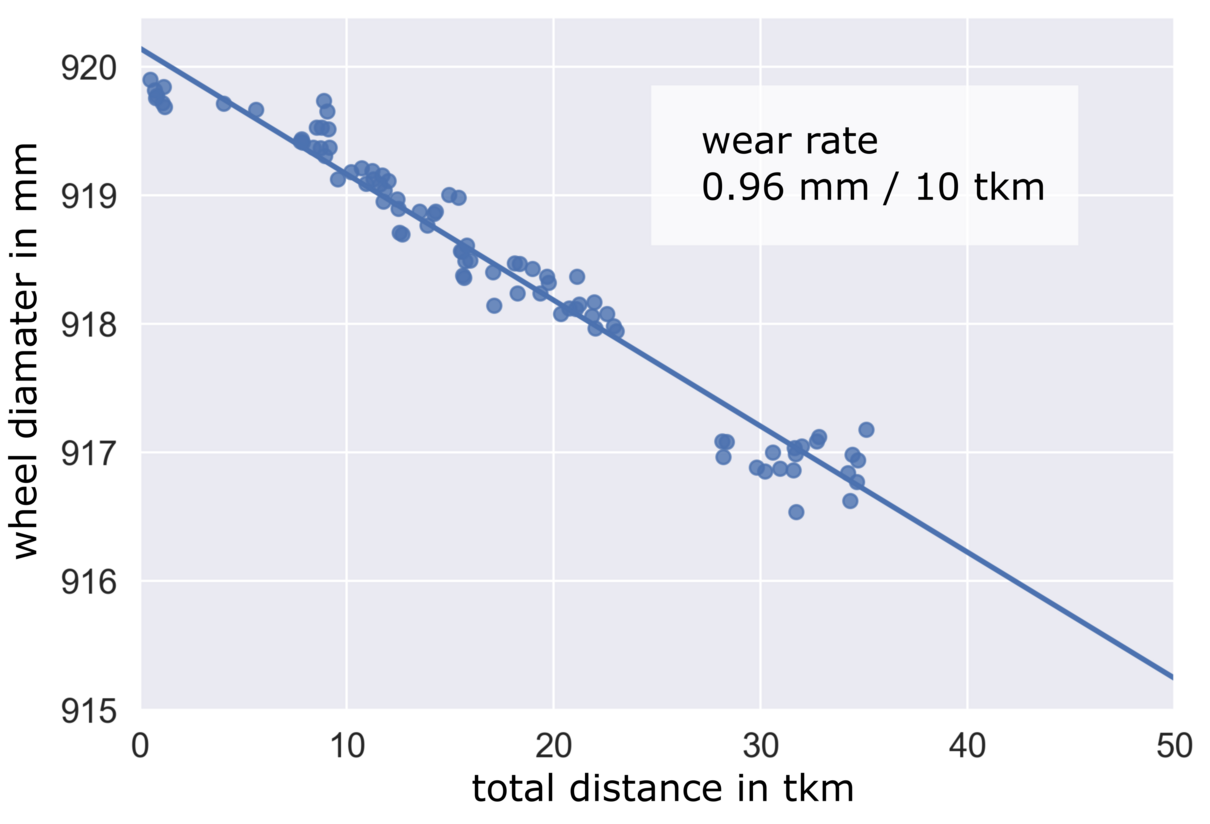

Predict – How can you simulate future conditions?

Predictive maintenance is essentially about reliably predicting future system behaviour and making suggestions for action at an early stage. A model-based approach is most effective for track maintenance machines. A physical model is defined in order to calculate variables derived from signal data or to compare data with a target condition.

One example of this is the method for determining the wheel wear rate without additional sensors. Here, speeds and distances from the GNSS signal are compared with the rotational speed of the axle transducers in order to calculate the wheel diameter and wear rate. Armed with this knowledge, maintenance measures and budgets can be systematically planned (Fig. 4).

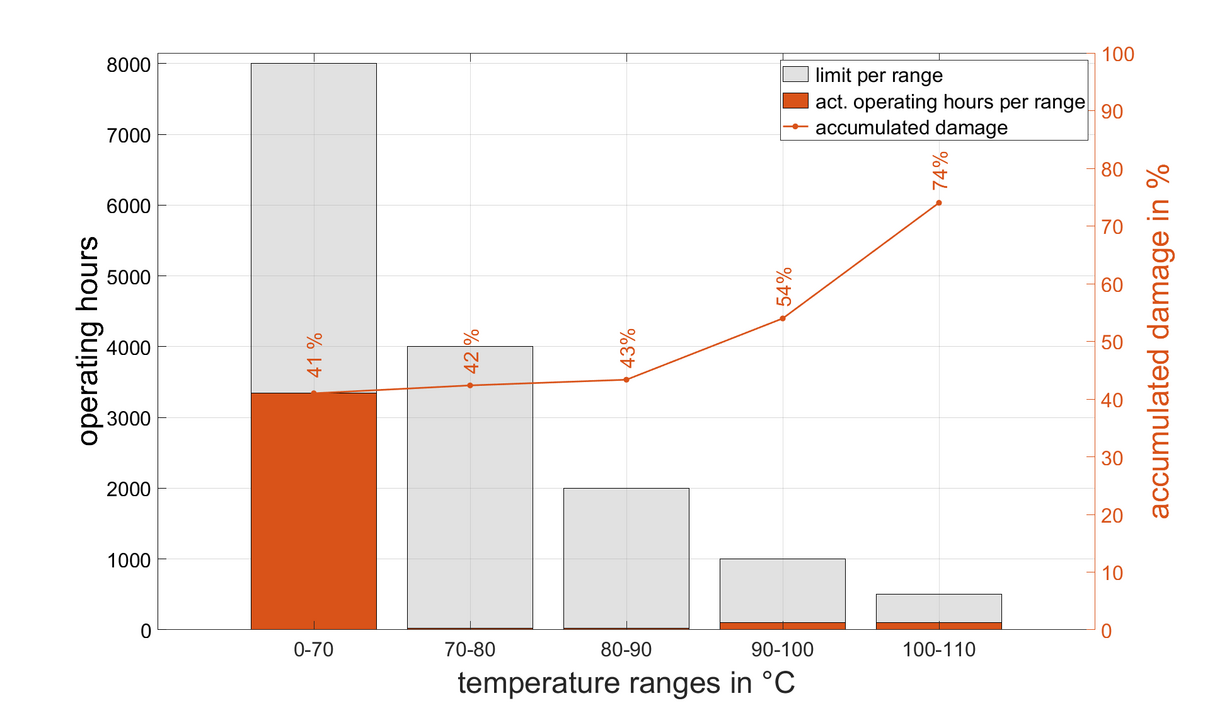

Intelligent oil-change intervals are a slightly different application. Temperature data from the hydraulic tank is used to determine oil ageing. Above 70°C, the oxidation rate increases exponentially. The remaining service life of the oil can be estimated from the measured temperatures, and the ideal time for an oil change can be predicted (Fig. 5). This saves costs and ensures that the oil is always in suitable condition. At the same time, unnoticed malfunctions that lead to increased oil temperatures can be detected.

Targeted use of AI

AI-supported analysis methods will also be used for certain components in the future. Research on AI-based methods for condition monitoring and predictive maintenance for tamping units is currently being conducted. The interaction of domain knowledge and AI can be highly useful for optimizing maintenance and operation if this is done in a targeted manner.

Deriving specific recommendations for action from machine data offers significant added value for machine operating companies. The challenge of extracting relevant information from the multitude of data can best be mastered by using intelligent analysis methods based on comprehensive knowledge of the system.

Maintenance strategies compared

| | Predictive | Preventive | Reactive |

|---|

| Planning | As required based on a component’s behaviour | Fixed intervals based on statistical considerations | In the event of a component failure |

|---|

| Advantages | Targeted, cost-efficient maintenance; maximized reliability and availability | Easy to implement, higher reliability and availability than reactive maintenance | Full utilization of the life of a component, no complex planning |

|---|

| Disadvantages | Usually requires additional technology for recording, requires expertise and resources for modelling and analysis | Tendency towards overservicing, labour-intensive | Repair and downtime costs are often higher than the added value from full utilization of the component life |

|---|