- Infrastructure

- Conventional lines

- High speed

- Field of application

- Turnout

- Plain-line track

- Working mode

- Spot maintenance

Highlights

- Integrated trailer for ballast bed profiling

- The machine can be used as regional track inspection vehicle

- Detect and repair isolated defects quickly and easily

- High return on investment factor ensures cost-efficiency

- Ballast bed profiling following tamping – the track can be reopened for traffic immediately after maintenance

- High quality work on plain-line tracks and in turnouts (Plasser & Theurer tamping technology, 3-rail lifting without support on the ballast bed)

- Optimal position of all control desks for work and transfer travel

- Best view of the working area, also during transfer travel

- Approval for line category C2 (axle load ≤ 20 t)

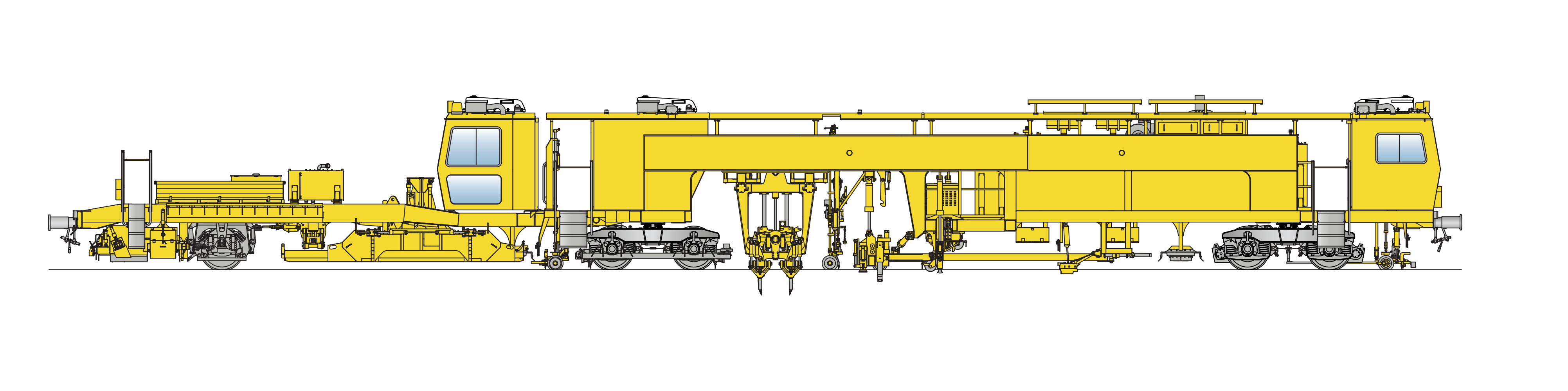

Machine illustration

Unimat Combi 08-275

zoomInzoomOut

Features

Quality cuts costs: our machines turn a tidy profit

To date, Plasser & Theurer has supplied 17,800 machines. Most of them are still in operation. This attests to the quality of the machines and the value of our Customer Services’ life-long machine and fleet support. Plus, it proves that high quality ensures high cost-efficiency: machines that have been in operation for 20 or 30 years paid off years ago.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.