- Infrastructure

- Conventional lines

- Heavy haul

- High speed

- Field of application

- Ballast bed

- Turnout

- Plain-line track

- Working mode

- Continuous action

Highlights

- Resource-saving working and reduced need for new ballast thanks to spot ballasting and 10 m³ ballast hopper including floor conveyor and automatic monitoring of the filling level

- Adjustable brush shaft enables sweeping of various sleeper types without replacing the brush

- Increased performance thanks to optimized transport of ballast into the ballast hopper

- One-pass technology: ballasting, profiling, and sweeping in one pass

- Increased working comfort thanks to working in a seated position, improved visibility of the working area, and HVAC system for optimum air conditioning in the cab

- Extending the two-part shoulder plough within the working profile enables the adjacent track to remain in service

- Fit for the future with ETCS integration

- Optional dust-suppression system for reducing dust

Technical data

To view the technical data and download a factsheet on this machine, please enter your contact details.

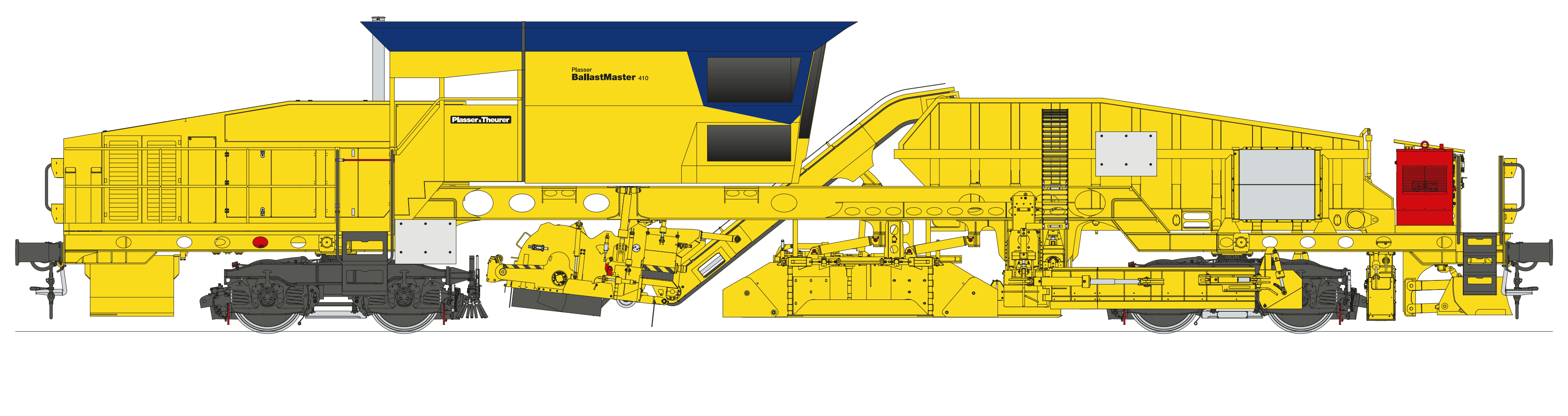

Machine illustration

Plasser BallastMaster 410

zoomInzoomOut

Enjoy the benefits of standardization with ModularCustomizing

We manufacture machines in our ModularCustomizing category based on a platform strategy. This makes maintenance, spare parts management, training, and approvals more efficient while tailoring them to your needs. More than 300 machine versions from the modular design kit. Thousands of configuration options.

Illustrations and descriptions may contain optional equipment. We reserve the right to make changes as technology develops.